Navigating structural concerns in your home can be a daunting task, but rest assured, Solidbase has a wealth of experience assisting homeowners in similar predicaments. We understand the gravity of such situations, and more importantly, we have the means to provide you with the answers you are seeking and valuable advice on how to proceed confidently.

At Solidbase Laboratory, we offer a comprehensive suite of services designed to meet all your testing and analysis needs, from initial sampling to the final presentation of expert reports. Our process begins with meticulous sampling, ensuring that samples are representative and collected according to industry standards. Our skilled technicians then conduct thorough analyses using advanced equipment and methodologies, adhering to stringent quality assurance protocols to guarantee accurate and reliable results.

Structural Surveys

A powerful combination of our in-house expertise together with industry standard investigation techniques enable us to provide the following structural surveys among others:

- Depth of carbonisation

- Half-cell potentiometer

- Cover meter

- Crack measurement and monitoring

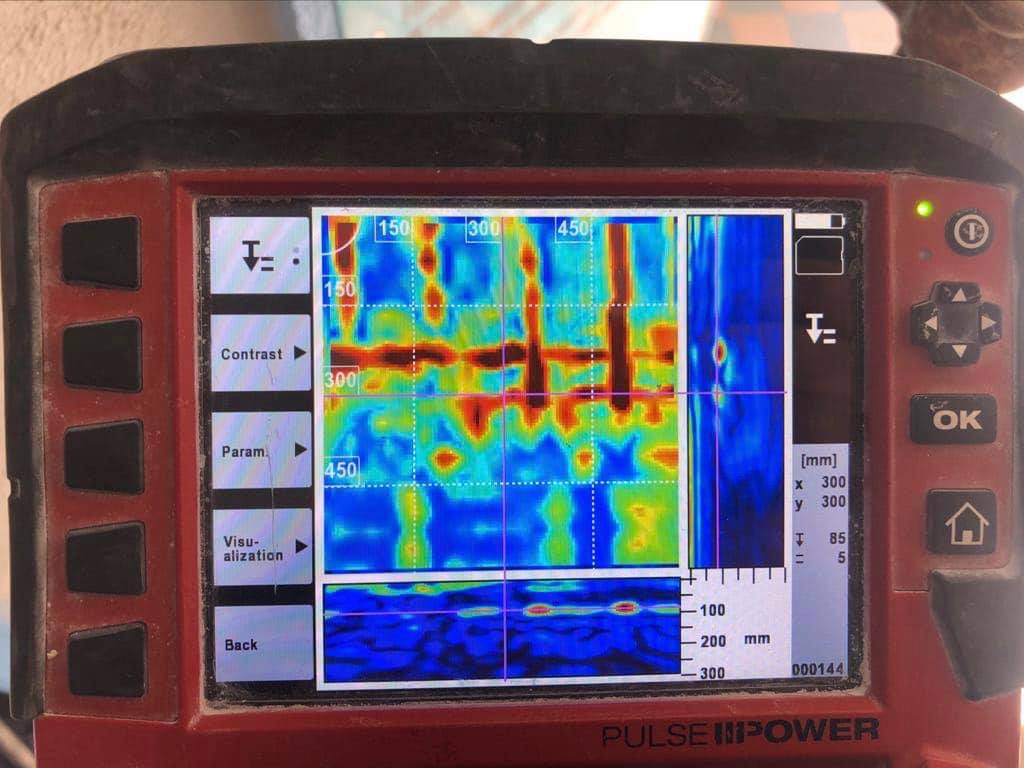

- Ground Penetrating Radar (GPR)

- Thermography

- Vibration monitoring

- Load / deflection performance

- Strain measurement

- Ultrasonic Pulse Velocity (UPV) testing

- Remote CCTV (borescope) inspections

- Concrete petrography

- Cause of failure and the presence of defects

Structural repairs are a crucial process aimed at restoring the strength and stability of a damaged or weakened structure, ensuring it can continue to perform its intended function safely. The process begins with a thorough assessment of the damage to determine both its extent and underlying cause. This initial evaluation is critical as it informs the most effective repair strategy, ensuring that all issues are addressed comprehensively.

For spalled, damaged, or carbonated concrete, various techniques can be employed to restore integrity. A common approach involves cleaning and treating the exposed reinforcement. This step is essential to remove any rust or corrosion, thereby preventing further deterioration. Once the reinforcement is adequately treated, it is reinstated using thixotropic high-strength repair materials or grout, which are specifically designed for structural repairs. These materials are applied to fill gaps, cracks, or voids, thereby restoring the concrete to its original strength.

In some instances, advanced methods such as carbon fiber reinforcement systems are used to enhance the structural integrity further. Carbon fiber systems are particularly beneficial due to their high strength-to-weight ratio and their ability to conform to various structural shapes, providing additional support without adding significant weight.

Once the repairs are completed, the structure undergoes rigorous testing to ensure it meets the required safety and reliability standards. This testing phase is crucial to verify that the repairs have been successful and that the structure is fit for continued use.